Design Natural stone Veneer

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Dalian,Qindao |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Dalian,Qindao |

Brand: Lijian

Material: Steel

MOQ: 1 Set

Certification: Other

Type: Tunnel Formwork

Surface Treatment: Painted Or As Customer Requirement

Application: Tunnel Engineering

Tolerance: Gb Or As Customer Requirements

Design: Provided By Li Jian

| Selling Units | : | Set/Sets |

| Package Type | : | According to customers request |

The file is encrypted. Please fill in the following information to continue accessing it

UHPC shading elements create

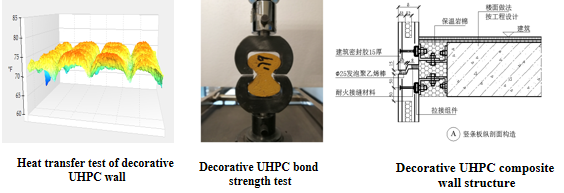

Ultra high performance concrete (UHPC) is somewhat “new” to the façade rainscreen marketplace. Taking advantage of various manufacturing approaches, there are a variety of UHPC or fiber concrete panels available. The ability to achieve large format sizes, as well as a large range of finishes and custom capabilities, has quickly allowed fiber concrete panels to become very popular within the rainscreen design community.

The UHPC stone veneer is a thin lightweight composite façade panel made from Natural Stone Veneer backed with ultra-high performance concrete. This stone-faced precast solution is creating a new future for prefabricated architecture, by creating classic, stone looking facades that are lightweight, making it easier to use on buildings.

Ae-uhpc, coarse aggregate UHPC product, expansion ≥ 600mm, 1-day compressive strength ≥ 90Mpa, 7-day compressive strength ≥ 150MPa, breaking the technical monopoly of SBT.

Technical indexes of UHPC products containing coarse aggregate

| Product model | AE-UHPC-120 | AE-UHPC-150 | AE-UHPC-200 |

| Standard value of compressive strength/MPa | ≥120 | ≥150 | ≥200 |

| 1-day compressive strength/MPa | ≥80 | ≥90 | ≥90 |

| Standard value of flexural tensile strength/MPa | ≥20 | ≥22 | ≥26 |

| Modulus of elasticity/GPa | ≥48 | ≥54 | ≥56 |

| shrink/ | ≤250 | -- | |

| Impermeability | >P12 | ||

| Frost resistance | >F400 | ||

Beijing Lijian ae-uhpc core technology

Self developed slump early strength agent with small slump loss,25% increase in strength in one day

Optimize the core components and ensure no shrinkage of strength at long age

| Product model | AD-UHPC-100 | AD-UHPC-120 | AD-UHPC-140 |

| Standard value of compressive strength/MPa | ≥100 | ≥120 | ≥140 |

| Heat transfer coefficient of composite wall/ W/( m2·K) | <0.4 | <0.4 | <0.35 |

| Interfacial bond strength/MPa | ≥6 | ≥7 | ≥7.5 |

| Standard value of flexural tensile strength/MPa | ≥23 | ≥25 | ≥28 |

| Modulus of elasticity/GPa | ≥38 | ≥40 | ≥42 |

| shrink/ | ≤800 | -- | |

| Impermeability | >P12 | ||

| Frost resistance | >F400 | ||

Beijing Lijian decoration UHPC product features

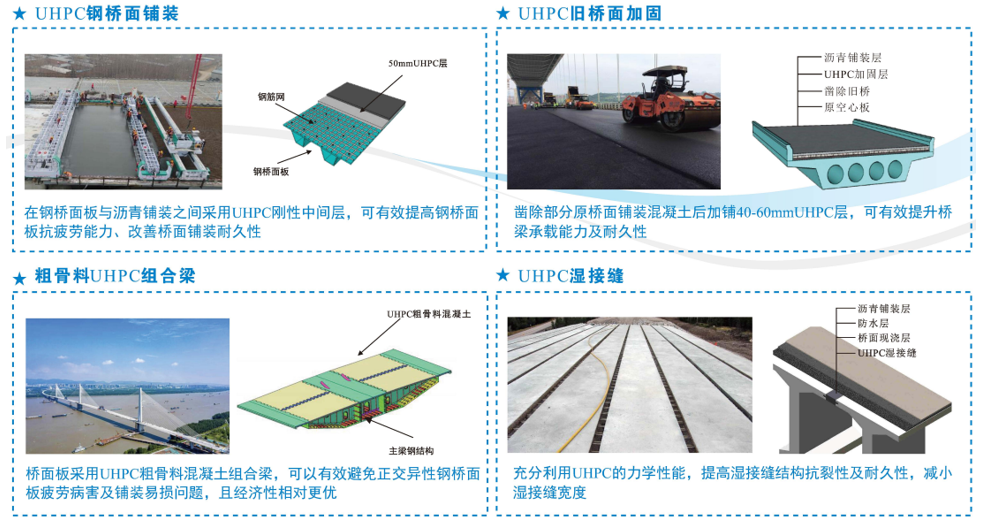

Project Overview: Both bridges are steel UHPC light composite structures, with a total area of 12700 ㎡ of UHPC deck pavement. The main bridge of Tuhai River Bridge on Heilongjiang Road adopts steel structure half through truss arch bridge, with a total length of 252m and a width of 46m. Xinghua Road Tuhai River Bridge is 2 × 100m double cable plane steel arch tower single tower cable-stayed bridge, with a total length of 200m and a width of 40m.

Technical proposal:Control technology of shrinkage cracking in winter construction、Composite viscosity reduction technology (viscosity reduced by 40%)、Ground material application technology.

Technical indicators of Beijing Lijian UHPC products

| Product model | A-UHPC -120 | A-UHPC -140 | A-UHPC -160 | A-UHPC -200 | AE-UHPC -120 | AE-UHPC -150 | AE-UHPC -200 |

| compressive strength/MPa | ≥120 | ≥140 | ≥160 | ≥200 | ≥120 | ≥150 | ≥200 |

| 1-day compressive strength/MPa | ≥80 | ≥90 | ≥100 | ≥100 | ≥80 | ≥95 | ≥95 |

| Flexural tensile strength/MPa | ≥22 | ≥25 | ≥28 | ≥32 | ≥20 | ≥22 | ≥26 |

| Modulus of elasticity/GPa | ≥38 | ≥42 | ≥44 | ≥45 | ≥48 | ≥54 | ≥56 |

| shrink/ | ≤600 | -- | ≤250 | -- | |||

| Impermeability | >P12 | ||||||

| Frost resistance | >F400 | ||||||

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.